Gas turbine blades

The Heart of the Engine

Gas turbine blades are critical components within a gas turbine engine. These blades are responsible for converting the energy of hot gases into mechanical work, driving the turbine wheel and ultimately powering the engine.

Types of Gas Turbine Blades

- Compressor Blades: These blades are located on the compressor wheel and are responsible for compressing the incoming air.

- Turbine Blades: These blades are located on the turbine wheel and are responsible for converting the energy of hot gases into rotational energy.

Materials

- Nickel-based superalloys: These alloys are the most commonly used materials for gas turbine blades due to their excellent high-temperature strength, creep resistance, and oxidation resistance.

- Cobalt-based superalloys: These alloys are also used for gas turbine blades, especially in applications where corrosion resistance is a primary concern.

- Titanium alloys: These alloys are sometimes used for compressor blades due to their low density and good fatigue resistance.

- Ceramic materials: Ceramic materials are being explored for use in gas turbine blades due to their high-temperature strength and resistance to corrosion.

why are Gas turbine blade useful?

Gas turbine blades are crucial components that enable gas turbines to convert the energy of hot gases into mechanical work. Their efficient design, advanced materials, and cooling techniques allow them to deliver high power output, improve overall engine efficiency, and ensure reliable operation in various applications such as power generation, aircraft propulsion, and marine propulsion.

Gas turbine blade Design

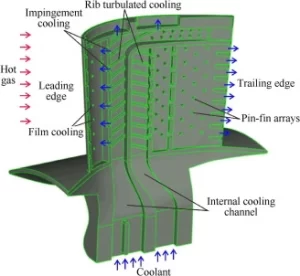

Aerodynamic design: Blades are designed to optimize airflow and minimize losses.

Structural design: Blades must be strong enough to withstand the high stresses and temperatures encountered in gas turbine engines.

Cooling channel design: Cooling channels must be designed to provide effective cooling while minimizing weight and complexity.

Environment and failure modes

Turbine blades are subjected to very strenuous environments inside a gas turbine. They face high temperatures, high stresses, and a potential environment of high vibration. All three of these factors can lead to blade failures, potentially destroying the engine, therefore turbine blades are carefully designed to resist these conditions.

these are subjected to stress from centrifugal force (turbine stages can rotate at tens of thousands of revolutions per minute (RPM)) and fluid forces that can cause fracture, yielding, or creep failures. Additionally, the first stage (the stage directly following the combustor) of a modern gas turbine faces temperatures around 2,500 °F (1,370 °C), up from temperatures around 1,500 °F (820 °C) in early gas turbines. Modern military jet engines, like the Snecma M88, can see turbine temperatures of 2,900 °F (1,590 °C). Those high temperatures can weaken the blades and make them more susceptible to creep failures. The high temperatures can also make the blades susceptible to corrosion failures. Finally, vibrations from the engine and the turbine itself can cause fatigue failures.

Application of Gas turbine blade

Gas turbine blades are critical components in gas turbine engines, which are widely used in various industries. These blades are responsible for converting the energy of hot gases into mechanical energy, driving the turbine rotor.

Here are some of the primary applications of Gas turbine blade:

Power Generation

- Power Plants: Gas turbine power plants are used to generate electricity, especially in peak load conditions or for emergency power supply.

- Combined Cycle Power Plants: Gas turbines are used in combined cycle power plants, where the exhaust heat from the gas turbine is used to generate steam for a steam turbine, increasing overall efficiency.

Aircraft Propulsion

- Jet Engines: Gas turbine blade is the core components of jet engines, powering commercial and military aircraft.

- Turboprop Engines: Turboprop engines, used in smaller aircraft, also rely on gas turbine blades for propulsion.

Marine Propulsion

- Ships and Boats: Gas turbine engines are used to power ships and boats, particularly those requiring high speeds or maneuverability.

Industrial Applications

- Compressors: Gas turbines are used to drive compressors in various industrial processes, such as oil and gas production, chemical processing, and manufacturing.

- Pumping: Gas turbines can power pumps for applications like water supply, wastewater treatment, and oil and gas extraction.

- Generators: Gas turbines can be used as emergency generators for critical facilities like hospitals, data centers, and manufacturing plants.

Other Applications

- Helicopter Propulsion: Some helicopters use gas turbine engines for propulsion.

- Trains: Gas turbine trains have been developed for high-speed transportation.

- Military Applications: Gas turbines are used in various military applications, including tanks, ships, and aircraft.

Maintenance and Inspection of Gas Turbine Blades

Regular maintenance and inspection of gas turbine blades are essential to ensure their continued performance and safety.

This involves visual inspection to check for signs of damage, such as cracks or erosion.Non-destructive testing techniques, like X-ray or ultrasonic inspection, are used to detect internal defects.Metallographic analysis is also performed to examine the microstructure of the blade material and assess its condition. By performing these inspections and maintenance tasks, engineers and technicians can identify and address potential problems before they lead to more serious issues like need to Compressor overhaul.

The three main components of a turbine blade: root, shroud and airfoil

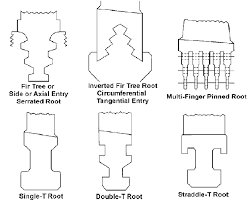

Root

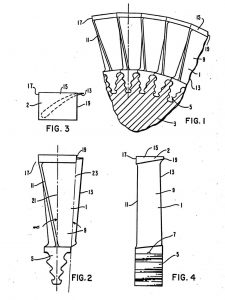

The root connects the moving blade to the rotor or the fixed blade to the housing.

By installing the fixed and moving blades side by side, a large circle of them is formed that interacts with the gas passing through the turbine or compressor. The shape of the root depends on the thermal and mechanical loads it must withstand over time. Design engineers must keep production costs low, but at the same time increase performance.

A more complex root design means a higher level of safety due to higher load carrying capacity, but this also means higher production costs. Creating the exact shape of the root requires special tools and more advanced methods in the manufacturing process. The connection of the fixed and moving blade to the rotor/housing is usually done through a suitable form or by a welded joint.