Gas Turbine Overhaul

Gas Turbine Rotor Overhaul

Kian Turbo Tec offers a competitive alternative for gas turbine owners and operators in the overhaul of rotors. Dedicated rotor overhaul engineers offering knowledgeable advice, experience of commercial operation, and an ex-stock supply of necessary components and rotating parts, ensure a committed response in returning users equipment to commercial operation as fast as possible with appropriate documentation and reports.

⦁ Pre–stripdown balance and inspection

⦁ Rotor disassembly

⦁ NDT facilities

⦁ Individual blade and wheel coating

⦁ Latest coating technologies

⦁ Individual wheel balancing

⦁ Rotor re-blade

⦁ Rotor reassembly

⦁ Rotor balance and run-outs

⦁ Rotor storage containers

⦁ Comprehensive customer reports

Customers can also take advantage of Turbine Services rotor exchange programmer. We always have available sufficient new or refurbished components to assemble turbine and compressor rotors at short notice. Customers are invited to benefit from this service. For cost-effective maintenance, customers may consider exchanging their operating rotor for a previously overhauled fully refurbished rotor which can be pre-delivered to site awaiting the next overhaul commencement

Pre–strip down balance and inspection:

Rotor balancing before disassembly to inspect all visual defects (VT) and unbalances that have formed on the Rotor.

Rotor disassembly:

Rotor disassembly:

Complying with safety and performance standards Gas Turbine Rotor disassembly is completed till Component level.

NDT facilities:

We provide VT (Visual Inspection), PT (Penetrant Test), MT (Magnetic Tests) & UT(Ultrasonic) testing to observe any defects or abnormalities, collection of data and in result quality insurance of the gas turbine components.

Rotor Overhaul Services

Individual wheel balancing:

Specification of any inconsistent weight distribution around the diameter of the rotor. Here in Kian Tec our field balancing capabilities include single and multi-plane balancing.

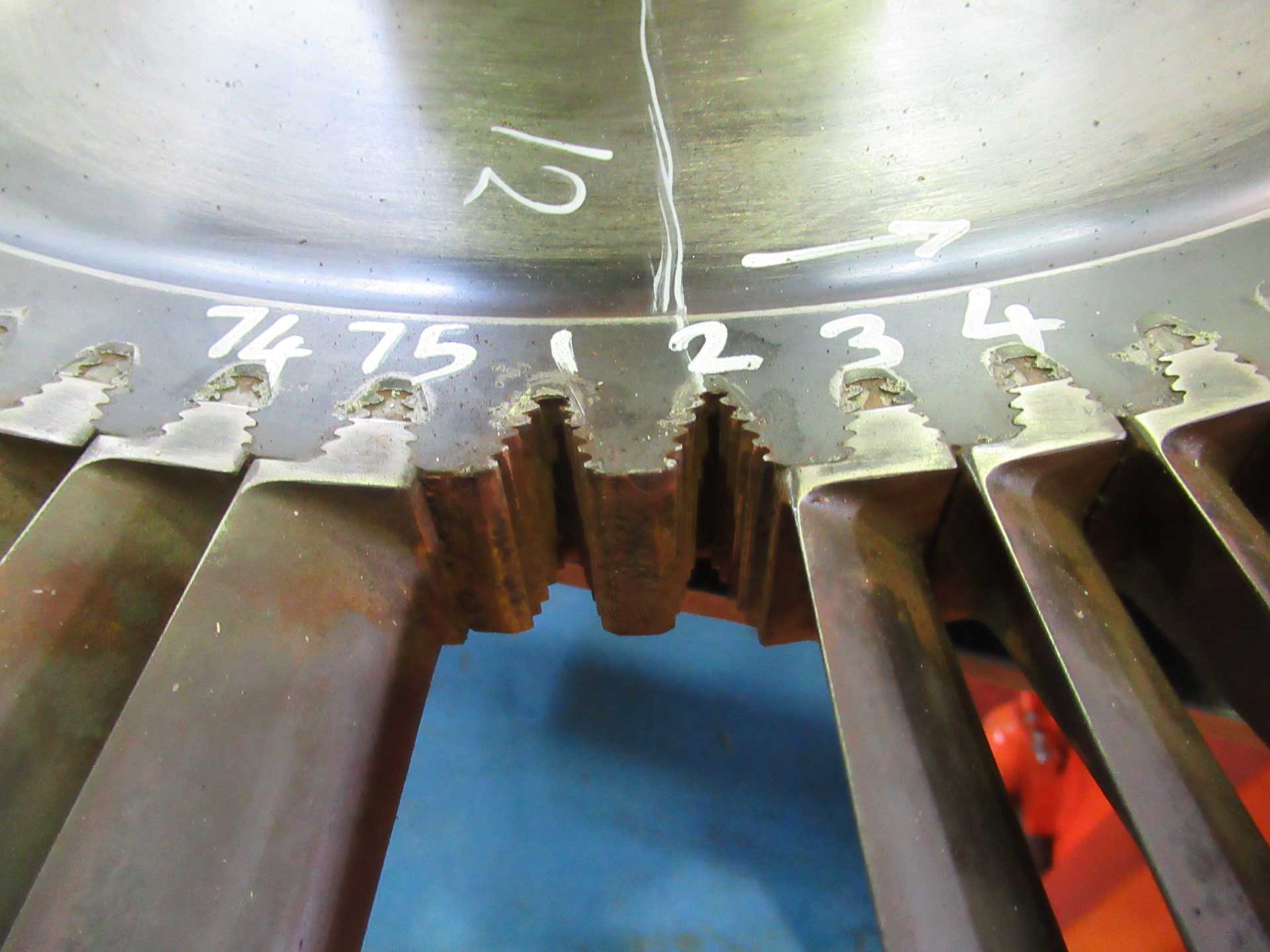

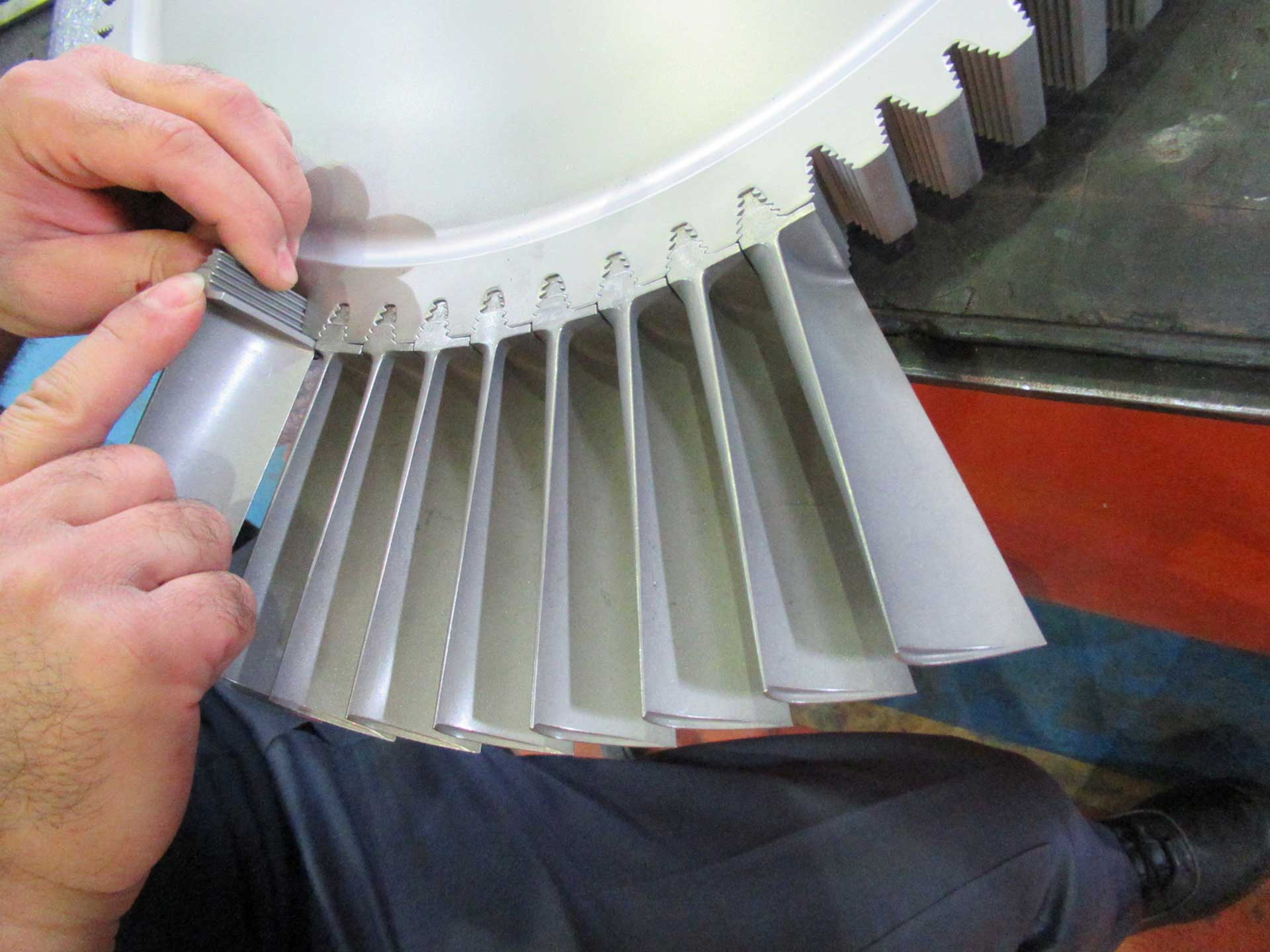

Rotor re-blade:

Inspection and Reparation of all Rotor Blades with appropriate

Rotor re-assembly:

All parts that were de-montaged (disassembled), repaired, renewed balanced and other maintenance processes that were performed will now be assembled with the same performance standards that were used for disassembly.

Rotor balance and run-outs:

Final Runouts are conducted so as to maximize efficiency and minimize vibrations, resonance and noise. Here in Kian Turbo Tec, we use the latest balancing solutions provided by SCHENCK according to ISO1940 standards to ensure the best results.

Comprehensive customer reports:

In order to meet customer expectations detailed full professional reports are prepared that indicates our step-by-step methods with accurate and need to know descriptions.

Component Repair Services

Kian Turbo Tec offers the most comprehensive independent gas turbine repair service in the world. Supported by state-of-the-art-technologies and capabilities of our parent company, Chromalloy, Turbine Services has extensive experience in repairing and refurbishing all component parts associated with gas turbines and related power equipment.

Specialized repairs & coatings

Our repair services include the refurbishment of all critical parts in the compressor, combustion and hot sections. Our regional workshop capabilities include:

⦁ Specialized vacuum furnace for super alloys

⦁ Metallurgical laboratory and component life evaluations

⦁ Full NDT testing and conditional reporting

⦁ Advanced alloy welding

⦁ Laser welding

⦁ Induction welding

⦁ Chamber welding

⦁ Advanced braze repairs

⦁ Hydrogen fluoride Ion cleaning

⦁ Hot isostatic pressure (HIP) rejuvenation heat treatment

⦁ Fuel nozzle test & flow matching

⦁ Flow divider, pump & valve testing

⦁ Bearings & associated deflectors

For more specialized repairs, Turbine Services offers a complete range of high technology coating processes, including many developed and patented by our parent company Chromalloy:

⦁ Electron beam physical vapor deposition coating (EBPVD)

⦁ Platinum aluminide coatings

⦁ Low pressure plasma spray coatings (LPPS)

⦁ High velocity oxy fuel coatings (HVOF)

⦁ Pack cementation coatings

⦁ Plasma spray thermal barrier coating (TBC)

⦁ Advanced protective hard face and anti-fretting coatings

Individual blade and Nozzle coating:

Coating materials such as Sermetel W, Sermalloy J, Aluminide. Are applied with different thickness levels depending on the part condition and thermal and corrosive resistance and other resistances to improve life span and reduce any damages which may apply to the part during the Turbines work hours.

Parts repair by using machine

Hit treatment

Coating Technology: HVOF (High velocity oxyfuel), Pack cementation.

CNC/Manual Dro heavy duty Lathing Machine

CNC/Manual Milling Machines

Welding Technology

Welding Technology: Kian Turbo Tec offers MIG, TIG, SAW, SMAW, Laser Welding, Plasma Welding, Submerged Welding services.