Ultimate Guide to Gas Turbine Blades

Ultimate Guide to Gas Turbine Blades : Design, Function, and Innovations

As experts in the overhaul of gas turbine components, Kian Turbo Tec is committed to enhancing the performance and reliability of Gas Turbine Blades . Our specialized services ensure that your turbine operates at peak efficiency, extending its lifespan and reducing downtime. Contact us today to learn how we can assist in optimizing your gas turbine systems

Introduction

Gas turbine blades are critical components in gas turbines, responsible for transforming energy generated from combustion into mechanical energy. These blades play a pivotal role across various sectors, from aviation to power generation. This guide explores the intricate design, function, and the latest innovations of gas turbine blades, providing insights for engineers, researchers, and industry professionals.

What Are Gas Turbine Blades?

Gas turbine blades are specialized components designed to endure extreme conditions while efficiently extracting energy from high-pressure, high-temperature gases produced during the combustion process. Their functionality is essential for optimal turbine performance, affecting both efficiency and operational reliability.

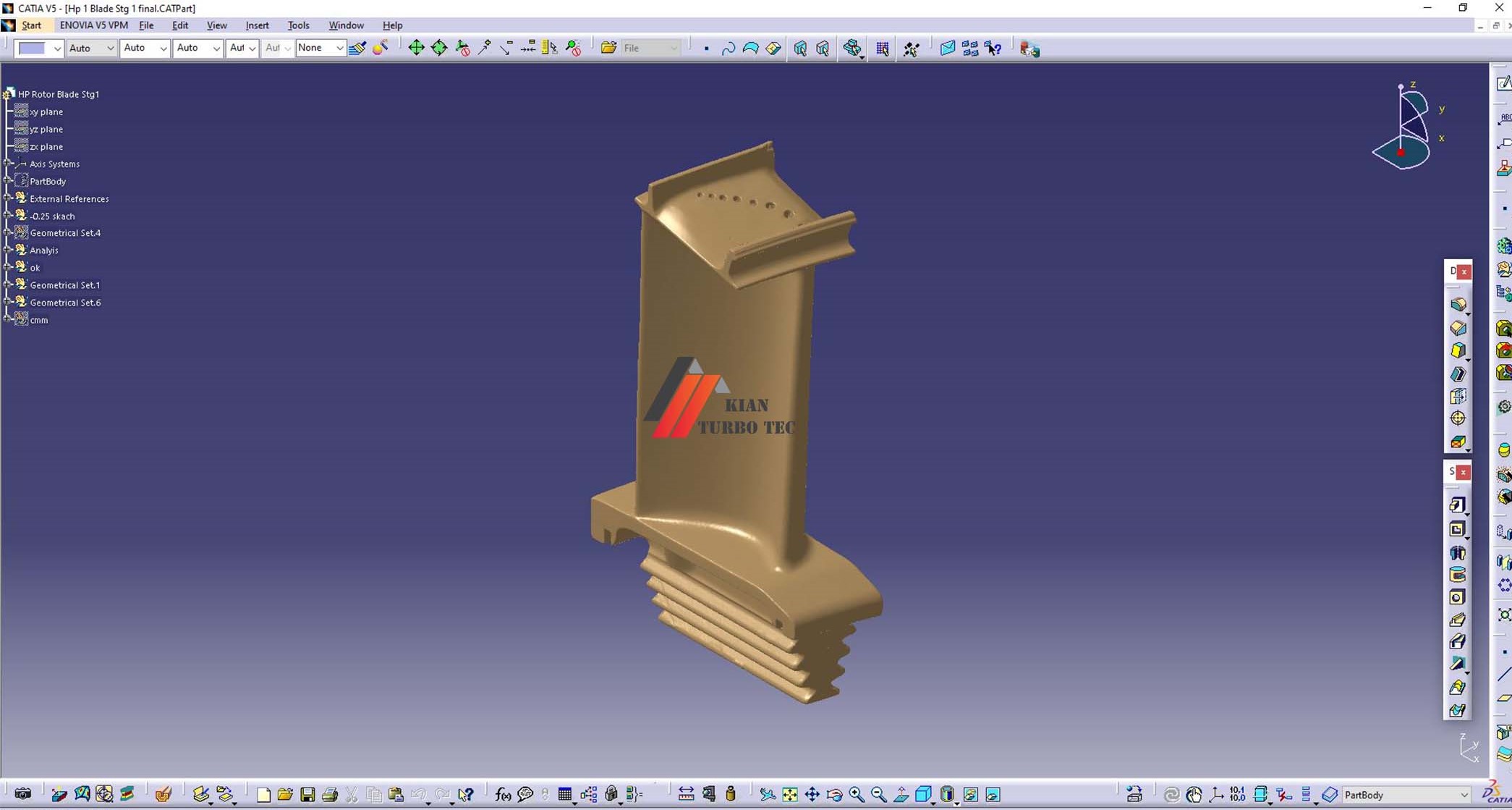

Figure 1 Sulzer S1 Gas Turbine Blades, Manufactured in Kian Turbo Tec

Key Features

Aerodynamic Design of Gas Turbine Blades

The aerodynamic design of gas turbine blade is crucial for efficient energy extraction. The airfoil shape of the blade is optimized to enhance airflow and maximize lift while minimizing drag. This design directly influences the overall efficiency of the turbine, making it a critical aspect of modern blade engineering.

Advanced Materials

Gas turbine blades must withstand extreme temperatures and mechanical stress. Therefore, materials used for blade manufacturing are designed for durability and performance. Common materials include:

– Nickel-based superalloys: Known for excellent resistance to oxidation and high-temperature stability.

– Ceramic matrix composites (CMCs): Emerging materials that offer lightweight solutions capable of withstanding high heat.

– Thermal Barrier Coatings (TBCs): Protective layers that enable blade to operate safely at higher temperatures, thus improving efficiency.

Innovative Cooling Techniques

To ensure longevity and performance, innovative cooling techniques are implemented in gas turbine blade:

– Internal Cooling Systems: These involve circulating cool air through internal passages within the blades to dissipate heat.

– Film Cooling Applications: A thin film of cooler air is injected on the blade’s surface to protect against extremely hot gases, enhancing blade life and performance.

How Gas Turbine Blades Function

Understanding the function of gas turbine blade is essential to grasping how gas turbines operate:

- Air Intake: Ambient air is compressed, raising its pressure and temperature.

- Fuel Combustion: The compressed air mixes with fuel, igniting and creating high-temperature gases.

- Gas Expansion: These gases expand through the turbine, causing the blade to spin and transfer mechanical energy.

- Energy Generation: The rotation of the blade ultimately powers generators or propels aircraft.

Figure 2 Assembly of Blades and Discs on Taurus 70 Gas Turbine, in Kian Turbo Tec Workshop

Recent Innovations in Gas Turbine Blade Technology

The gas turbine industry is experiencing rapid advancements in blade technology, including:

Manufacturing of Gas Turbine Blades:

3D printing, or additive manufacturing, allows for the creation of complex blade designs that optimize aerodynamic performance and reduce weight. This innovative manufacturing process facilitates the production of intricate cooling channels that improve engine efficiency.

Figure 3 Cloud Point Scanning of THM 1304Blades in Kian Turbo Tec workshop

Smart Technology Integration

The incorporation of sensors and IoT (Internet of Things) technologies in gas turbine blade has led to the development of smart blades, capable of real-time performance monitoring. This feature enhances reliability and minimizes maintenance costs by enabling predictive analytics.

Coatings of Gas Turbine Blades

Research continues into advanced thermal barrier coatings, aiming for enhanced durability and effectiveness. These innovations allow gas turbine blade to operate at even higher temperatures, significantly improving overall turbine performance.

Gas turbine blades are a cornerstone of gas turbine technology, influencing efficiency, reliability, and performance across various industries. With continual advancements in materials, cooling techniques, and manufacturing processes, the future of gas turbine blade looks promising. As industries strive for higher efficiency and sustainability, these innovations are essential in meeting modern energy demands while addressing environmental challenges.

FAQs

1. What materials are gas turbine blades made from?

– Gas turbine blades are typically made from nickel-based superalloys and ceramic matrix composites, known for their high-temperature performance.

2. How do cooling techniques improve gas turbine blades

– Cooling techniques such as internal cooling and film cooling help manage temperature, preventing blade deformation and extending their service life.

3. What is the role of aerodynamics in gas turbine blades?

– The aerodynamic design of blade minimizes drag and maximizes lift, significantly impacting turbine efficiency.