Gas Engine

Gas Engine , Gas Turbine is an internal combustion engine of rotary machines that operates on the energy of combustion gases. It is mainly used in power plants, but helicopter engines, passenger aircraft engines, warplane engines and ship turbine engines are also types of gas turbines.They are used in a wide variety of applications, including cars, trucks, boats, generators, and power plants.

Advantages of gas turbines Power to weight ratio: Gas turbines are smaller than reciprocating engines with the same power. Gas turbines are one of the power generation machines that are widely used today in various industries such as power plants, refineries, petrochemicals and oil and gas industries.

A gas engine works by taking in a mixture of air and gasoline, compressing it, and then igniting it. The explosion of the gasoline creates power, which is used to turn the engine’s crankshaft. The crankshaft then turns the wheels of the vehicle or the generator.

A Gas turbine is a specialized rotating engine that has the ability to extract and produce the desired energy from a fluid.

Solar Taurus are comprised of Solar Turbine parts, gas turbine overhaul , field service, flexible service agreements, digital solutions. and technical training in addition to remote web based monitoring and predictive diagnostic capabilities.

Commissioning Gas Turbine Installing a gas turbine in this power plant, in addition to increasing productivity, will bring many financial benefits by reducing environmental pollution and saving maintenance and support costs.

There are two main types of gas engines:

Spark-ignition (SI) engines: These engines use a spark plug to ignite the fuel-air mixture in the combustion chamber. They are the most common type of gas engine, and are used in most cars and trucks.

Compression-ignition (CI) engines: These engines use the heat of compression to ignite the fuel-air mixture. They are less common than SI engines, but are used in some diesel cars and trucks, as well as in heavy machinery.

Within these two main types, there are a number of different gas engine designs. Some of the most common include:

Inline engines: These engines have the cylinders arranged in a straight line. They are the simplest and most compact type of gas engine, and are often used in small cars and motorcycles.

V-engines: These engines have the cylinders arranged in a V-shape. They are more powerful than inline engines, and are often used in larger cars and trucks.

Rotary engines: These engines have a triangular rotor that rotates inside an oval-shaped chamber. They are more efficient than traditional gas engines, but are also more complex and expensive.

Gas engines can be powered by a variety of different fuels, including gasoline, natural gas, propane, and biogas. The type of fuel used will affect the engine’s performance and emissions.

Very low start-up time compared to thermal turbines Less vibration:

Due to moving in one direction, the vibration of gas turbines is less than reciprocating engines. Less moving parts than reciprocating engines. Less lubrication cost

Kian Turbo Tec offers a competitive alternative for gas turbine owners and operators in the overhaul of rotors. Dedicated rotor overhaul engineers offering knowledgeable advice. experience of commercial operation. and an ex-stock supply of necessary components and rotating parts.

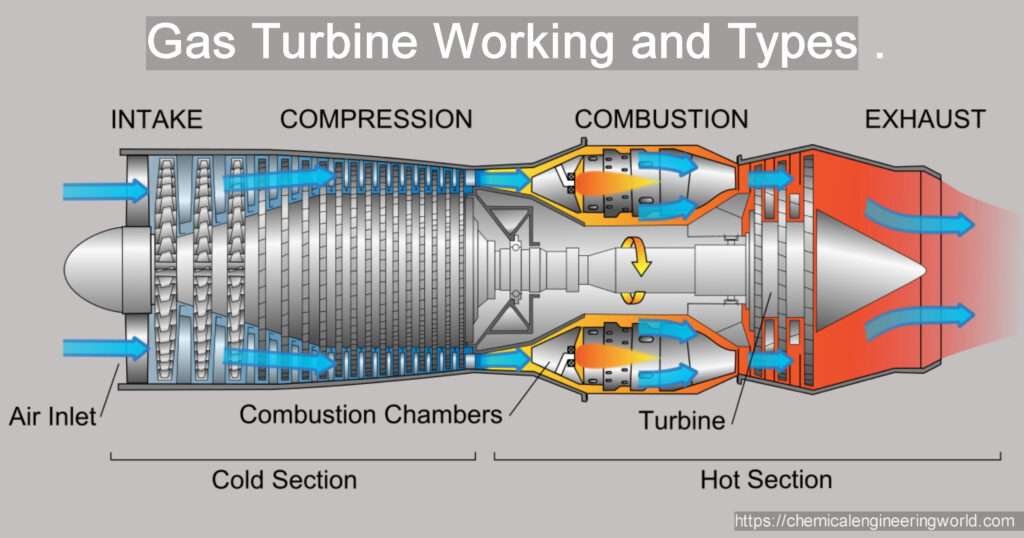

Each gas turbine includes a compressor to compress the air, a combustion chamber to mix the air with the fuel and ignite it, and a turbine to convert the internal energy of the hot and compressed gases into mechanical energy.

Part of the mechanical energy produced in the turbine is spent on the self-propelled turbine compressor. and the rest of the energy, depending on the application of the gas turbine, may spin the electric generator (turbogenerator). accelerate the air (turbojet and turbofan) either directly (or after Change). Rotation speed by gearbox) to be used in the same way (Turboshaft, Turboprop and Turbofen).

Gas Turbines

The first one is related to the Accessory Gearbox of the Turbine (Accessory Drive), the second part is related to the Compressor set including Inlet Guide Vanes (IGV), Stator Blades and the Compressor Rotor. In the following sections, the Turbine components, the Combustion Chamber and finally the Power Turbine components are dismantled.

Gas Turbine Overhaul and Kian Turbo Tec offers a competitive alternative for gas turbine owners and operators in the overhaul of rotors. Dedicated rotor overhaul engineers offering knowledgeable advice. experience of commercial operation.

Gas Turbine Components , The increasing use of gas turbines in various industries, especially in the oil and electronics industries. such as moving large pumps inside oil and gas pipelines. supplying energy required by factories and special areas away from the network is very significant and significant.

These turbines are very large and massive and a lot of metals are used in their construction. They are very difficult to maintain and most of the time a group of engineers use these turbines. These turbines have an internal combustion engine In a circular and rotational manner, they convert energy using the excitation of gases. These turbines are used in various industries and machines and their fuel is usually gas.

Some of Gas turbine Technologies

Gas turbine technologies are central to delivering efficient,flexible, and high-performance energy solutions for a wide range of applications,including power generation,industrial processes,and large-scale mechanical drives. The company specializes in advanced gas turbine systems that are designed for both optimal fuel efficiency and minimal environmental impact. Kianturbotec’s turbines are equipped with cutting-edge combustion technology, enabling them to operate on a variety of fuels, including natural gas, biogas, and other alternative fuels, ensuring operational flexibility and reducing dependency on a single fuel source.

The turbines incorporate advanced turbine blades and cooling technologies that enhance their performance under high-pressure and high-temperature conditions With digital control systems.

Kianturbotec turbines offer real-time monitoring and precise adjustments to maximize efficiency and performance, ensuring reliability in even the most demanding environments. Furthermore, the turbines are designed for low emissions through the integration of high-efficiency combustion systems,reducing CO2 and NOx emissions and meeting stringent environmental standards.

In addition, Kianturbotec focuses on combined cycle and combined heat and power (CHP) configurations,which improve the overall energy output by utilizing the waste heat from turbines for additional power generation or heating. This increases the system’s efficiency, making it an ideal solution for industries and utilities looking for both power and heat from a single energy source. Through continuous innovation and a focus on sustainability,

Ttechnologies in Kianturbotec,s Company are reliable,eco-friendly,and cost-effective solutions to meet the energy needs of a diverse range of industries.