Gas Turbine Components

Gas Turbine Components , Gas turbine components are in fact a rotating internal combustion engine from the family of turbomachines, which is known in the public mind as the most widely used aircraft jet engine.

The Gas Turbine Efficiency works by igniting the difference between compressed air and fuel and passing the product through a series of rotating disks of the turbine, which causes the rotational power of a shaft or creates a driving reaction force or a combination of these two phenomena.

In these turbines, some natural gas and compressed air are burned in the combustion chamber and due to the burning heat, the volume of gas increases and the gas hits the turbine blades with a large volume and a certain pressure and temperature and causes the turbine to rotate.

Iran has a high potential for using solar energy in power generation systems due to its abundant sunny areas. Solar gas turbine is one of the power generation systems that has been highly regarded by researchers and scholars in recent years.

Solar gas turbine

Among renewable energies, the sun, as an endless source of energy, has always been in the focus of researchers. The use of solar radiation energy in conventional power generation systems. such as gas turbines can play an important role in reducing fuel consumption and environmental pollution. On the other hand, this issue increases the efficiency of the desired cycles and improves their performance.

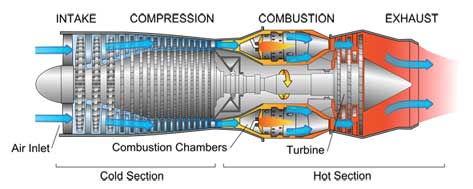

In general, it can be said that a gas turbine has five sections:

- Inlet air equipment

- A device for compressing air called a compressor,

- A bed for combustion reaction called combustion chamber

- A device for extracting work called turbine.

- Exhaust

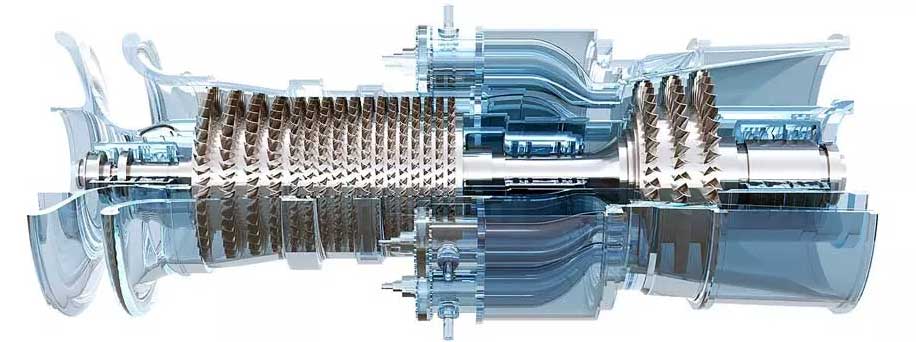

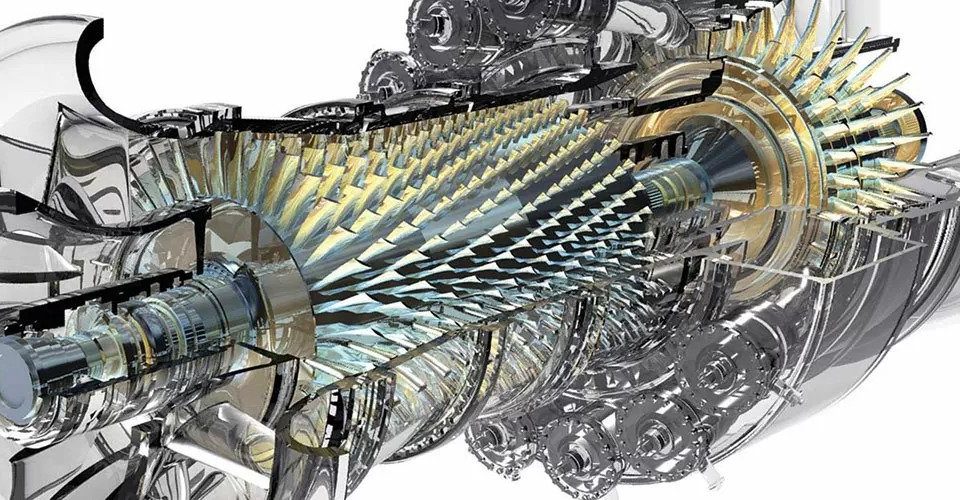

All parts of the gas turbine are housed inside a chamber called the Engine Case. This chamber is tubular in shape and its beginning and end are open and placed horizontally.

Air circulation and combustion gases or the operating fluid in a gas turbine can be studied in three main stages.

Step 1:

After purification, a large volume of air is sucked into the compressor at atmospheric pressure and ambient temperature through an inlet called the Engine Air Inlet. As the compressor rotates, this air is compressed inside the compressor, and as a result of this process, its temperature rises. As the pressure increases, the volume of air also decreases. This air exits the compressor with high pressure and high temperature.

Step 2:

Compressed air enters the combustion chamber. In this section, by injecting fuel, combustion takes place at a constant pressure and a flame is formed. In combustion, we are faced with the volumetric expansion of gases. This air leaves the combustion chamber under conditions of high pressure and very high temperature.

Step 3:

In this step, the operating fluid enters the turbine section. This section consists of steps in which each step has a larger volume than the previous step. In order for the working fluid to pass from one stage to the next, it must be able to move the resistive force, which is the turbine blades. Overcoming the resistive force and doing the work reduces the pressure and temperature of the operating fluid and its expansion. The maximum fluid can expand until it reaches ambient pressure. The operating fluid exits the turbine under atmospheric pressure and high temperature conditions.

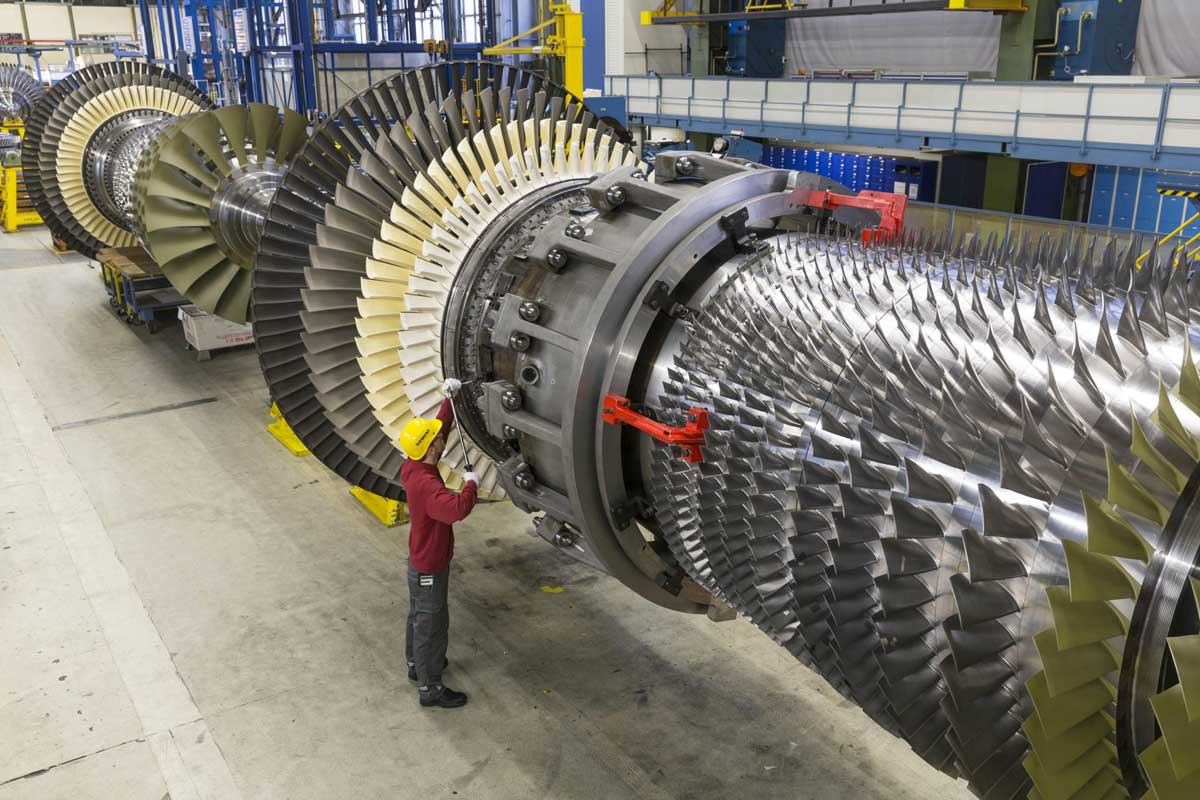

Gas Turbine Service Companies A number of blades mounted on a disc are located at the beginning of the chamber on an axis called the compressor. By rotating the compressor, the required combustion air is supplied, after which the fuel is mixed with this air and ignited. The resulting combustion creates a forward force. This force moves the blades mounted on a disk called a turbine, the axis of which is connected to the compressor shaft and causes the compressor to rotate.

SOLAR Taurus Gas Turbine

Kian Turbo Tec. is trying to meet as many industrial needs as possible with the aim of supplying and equipping all kinds of sensitive Mechanical and Electronic Components of Gas Turbines. Due to self-sufficiency, supplying all kinds of sensitive parts of SOLAR Taurus Turbine such as stator and rotating Blades in the hot section is another significant activity of this company.

Gas Turbines Service Companies, Each gas turbine efficiency has a compressor to compress the air. a combustion chamber to mix the fuel with the air and its combustion. and a turbine to convert the internal energies of the hot, high-pressure gases into mechanical energy.