Gas Turbine Overhaul

Gas Turbine Overhaul , Kian Turbo Tec offers a competitive alternative for gas turbine owners and operators in the overhaul of rotors. Dedicated rotor overhaul engineers offering knowledgeable advice. experience of commercial operation. and an ex-stock supply of necessary components and rotating parts. ensure a committed response in returning users equipment to commercial operation as fast as possible with appropriate documentation and reports.

Solar Taurus are comprised of Solar Turbine parts, gas turbine overhaul , field service, flexible service agreements, digital solutions. and technical training in addition to remote web based monitoring and predictive diagnostic capabilities.

Solar Mars

Solar Turbines has been an active agent in the field of industrial power generation for about 65 years. Solar Turbines have manufactured and designed sustainable and innovative products for oil and natural gas production.

Solar Turbines has been an active agent in the field of industrial power generation for about 65 years. Solar Turbines have manufactured and designed sustainable and innovative products for oil and natural gas production.

Iran has a high potential for using solar energy in power generation systems due to its abundant sunny areas. Solar gas turbine is one of the power generation systems that has been highly regarded by researchers and scholars in recent years.

gas turbine overhaul

Gas turbines are a critical part of many industrial and power generation applications. They can provide reliable and efficient power for many years, but they need to be properly maintained to keep them running at peak performance. A comprehensive overhaul is one of the best ways to extend the life of your gas turbine and ensure that it continues to operate safely and efficiently.

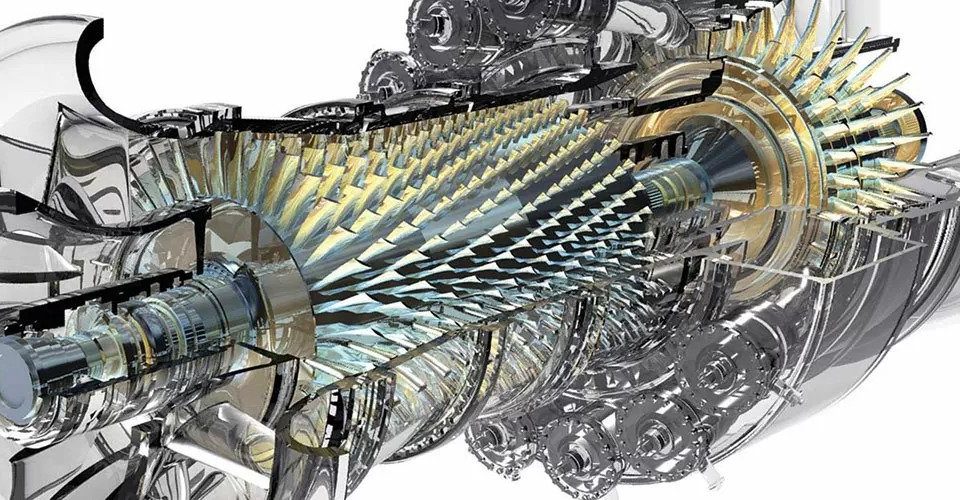

During an overhaul, all of the major components of the gas turbine are inspected, cleaned, repaired, or replaced as needed. This includes the compressor, combustion chamber, turbine, and other essential parts. The overhaul process also includes a thorough inspection of the gas turbine’s control system and other electrical and mechanical components.

A comprehensive overhaul can help identify and correct any potential problems with your gas turbine before they cause major damage. It can also help to improve the efficiency of the gas turbine, which can lead to significant savings on operating costs.

Benefits of Gas Turbine Overhaul:

There are many benefits to overhauling a gas turbine, including:

Improved performance: An overhauled gas turbine will operate more efficiently and produce more power.

Increased reliability: An overhauled gas turbine is less likely to experience failures.

Extended lifespan: A gas turbine overhaul can extend the lifespan of a gas turbine by many years.

Reduced maintenance costs: A well-maintained gas turbine is less likely to require costly repairs.

Gas Turbine Overhaul Costs:

The cost of a gas turbine overhaul will vary depending on the size and type of gas turbine, as well as the extent of the work required. However, the cost of an overhaul is typically much lower than the cost of replacing a gas turbine.

⦁ Pre–stripdown balance and inspection

⦁ Rotor disassembly

⦁ NDT facilities

⦁ Individual blade and wheel coating

⦁ Latest coating technologies

⦁ Individual wheel balancing

⦁ Rotor re-blade

⦁ Rotor reassembly

⦁ Rotor balance and run-outs

⦁ Rotor storage containers

⦁ Comprehensive customer reports

Customers can also take advantage of Turbine Services rotor exchange programmer. We always have available sufficient new or refurbished components to assemble turbine and compressor rotors at short notice.

Customers are invited to benefit from this service. For cost-effective maintenance, customers may consider exchanging their operating rotor for a previously overhauled fully refurbished rotor which can be pre-delivered to site awaiting the next overhaul commencement

The Need for Gas Turbine Overhaul

Gas turbines, be they industrial or aero-derivative, require regular overhaul services to ensure their continued safe and efficient operation. Overhaul involves a comprehensive disassembly of the turbine, followed by a meticulous inspection, cleaning, and the replacement of worn or damaged parts. It also includes various performance checks and tests before the turbine is reassembled and given a fresh coat of paint.

Extending Lifespan and Reducing Downtime

By replacing worn components during an overhaul, the operating lifespan of a gas turbine can be extended, resulting in reduced downtime and improved overall performance. This proactive approach can prevent more significant repairs that could be financially burdensome and time-consuming.

Utilizing quality components

To guarantee the longevity and performance of overhauled turbines, it is vital to use high-quality components. Reputable overhaul service providers typically utilize OEM parts or equivalent components that have been carefully inspected and approved for their performance and durability.

Pre–strip down balance and inspection:

Rotor balancing before disassembly to inspect all visual defects (VT) and unbalances that have formed on the Rotor.

Rotor disassembly:

Complying with safety and performance standards Gas Turbine Rotor disassembly is completed till Component level.

NDT facilities:

We provide VT (Visual Inspection), PT (Penetrant Test), MT (Magnetic Tests) & UT(Ultrasonic) testing to observe any defects or abnormalities, collection of data and in result quality insurance of the gas turbine components.

In gas turbines, gas plays the role of fluid for rotation. Most gas turbine engines include at least one compressor, combustion chamber and turbine. The complex acts as a main driver in a so-called cycle, in which air is taken from the atmosphere and the products of combustion are eventually returned to the atmosphere.

Gas turbine components are in fact a rotating internal combustion engine from the family of turbomachines, which is known in the public mind as the most widely used aircraft jet engine.

Mechanical Problems:

- Blade Damage: Erosion, corrosion, and fatigue can lead to blade damage.

- Bearing Failure: Overheating, contamination, and misalignment can cause bearing failure.

- Seal Leakage: Wear and tear can lead to seal leakage, resulting in loss of efficiency and contamination.

- Compressor Surge: Excessive pressure buildup in the compressor can cause surge, leading to vibrations and reduced efficiency.

- Turbine Overspeed: Overheating or control system malfunctions can cause the turbine to exceed its design speed.