Gas Turbine efficiency

Gas Turbine efficiency , Gas turbines are among the equipment that are widely used to generate power in power plants and refineries. Therefore, increasing the efficiency of gas turbines, which is one of the main power generation cycles, is of particular importance.

Gas turbine components are in fact a rotating internal combustion engine from the family of turbomachines, which is known in the public mind as the most widely used aircraft jet engine.

Solar Mars , Solar Turbines has been an active agent in the field of industrial power generation for about 65 years. Solar Turbines have manufactured and designed sustainable and innovative products for oil and natural gas production.

Iran has a high potential for using solar energy in power generation systems due to its abundant sunny areas. Solar gas turbine is one of the power generation systems that has been highly regarded by researchers and scholars in recent years.

SOLAR TURBINE SERVICES

Solar Turbine services are comprised of Solar Turbine parts. gas turbine overhaul, gas turbine field service, flexible service agreements, digital solutions, and technical training in addition to remote web based monitoring and predictive diagnostic capabilities.

The use of solar radiation energy in conventional power generation systems. such as gas turbines can play an important role in reducing fuel consumption and environmental pollution. On the other hand, this issue increases the efficiency of the desired cycles and improves their performance.

Gas Turbine efficiency

The study of the performance of gas turbines for its optimal operation has become of special importance in research centers around the world today.

Due to the fact that the fluid flow in gas turbines has a high speed and temperature, so the performance of the device is very sensitive to various parameters.

This sensitivity requires that the performance of the gas turbine be carefully evaluated in order to increase efficiency (reduce fuel consumption), increase component life, and reduce environmental pollution. In this project, a real sample has been studied.

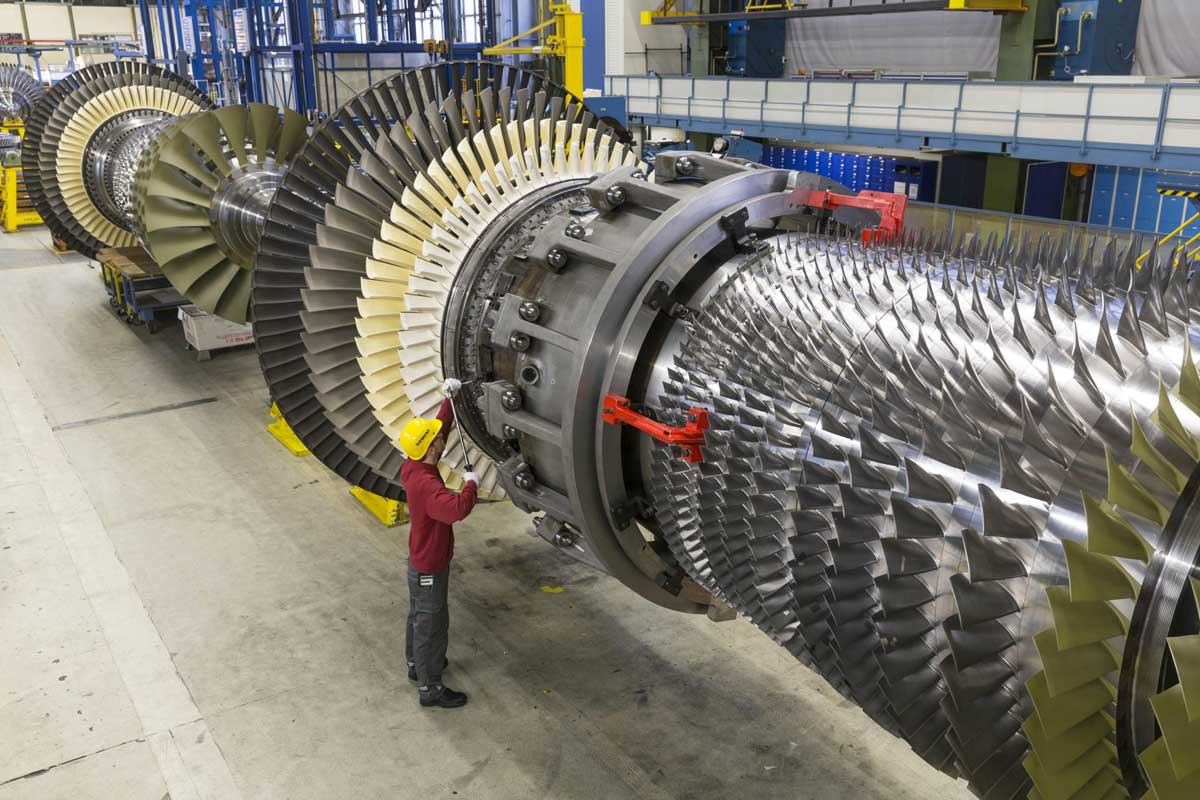

Gas Turbines

Each gas turbine has a compressor to compress the air, a combustion chamber to mix the fuel with the air and its combustion. and a turbine to convert the internal energies of the hot, high-pressure gases into mechanical energy. Part of the mechanical energy produced in the turbine is used in the compression of the gas turbine compressor. and the rest of the energy produced, depending on the intended use for the gas turbine. may cause the electric generator (turbogenerator) to spin in accelerating the air. Role (turbofen and turbojet) or consumed directly in the same production (turbofen, turboprop and turboshaft).

The optimization of steam power plants with fossil fuels is being considered all over the world in order to increase the final production of power. There are different solutions to increase the efficiency of existing power plants using gas turbines. The choice of the optimal solution is based on the size and technical conditions of the existing power plant on the one hand. and on profitability and economic efficiency indicators on the other hand.

Gas turbine components are in fact a rotating internal combustion engine from the family of turbomachines, which is known in the public mind as the most widely used aircraft jet engine.

Solar Mars

Solar Taurus are comprised of Solar Turbine parts, gas turbine overhaul , field service, flexible service agreements, digital solutions. and technical training in addition to remote web based monitoring and predictive diagnostic capabilities.

GAS ENGINE

Kian Turbo Tec offers a competitive alternative for gas turbine owners and operators in the overhaul of rotors. Dedicated rotor overhaul engineers offering knowledgeable advice. experience of commercial operation. and an ex-stock supply of necessary components and rotating parts.

Combined Cycle Gas Turbine (CCGT) Efficiency

Combined cycle gas turbines (CCGTs) are highly efficient power plants that utilize both gas and steam turbines to generate electricity.

This two-stage process significantly improves overall efficiency compared to traditional gas turbine or steam turbine power plants.

How CCGTs Work

Gas Turbine Cycle: Natural gas is combusted in a gas turbine, generating hot exhaust gases. These gases drive the turbine, producing electricity.

Heat Recovery Steam Generator (HRSG): The hot exhaust gases from the gas turbine are then directed through a heat recovery steam generator (HRSG). This heat is used to convert water into steam.

Steam Turbine Cycle: The high-pressure steam produced in the HRSG drives a steam turbine, generating additional electricity.

Factors Affecting Gas Turbine Efficiency

1.Compressor and turbine design

The efficiency of the compressor and turbine stages directly impacts overall performance.

Modern, advanced turbines have more stages and can operate at higher pressure ratios, which improve efficiency.

2.Combustion process:

Efficient combustion leads to better energy conversion. The more completely the fuel burns, the higher the efficiency.

3.Temperature and pressure ratios

Gas turbines typically work at higher efficiencies when the temperature of the exhaust gases is higher and the pressure ratios are optimized.

4.Environmental conditions

Higher ambient temperatures can lower efficiency as the turbine has to work harder to compress hot air.

Challenges in Increasing the Efficiency of Gas Turbines

- Thermodynamic Limits

Gas turbines operate based on thermodynamic cycles, and their efficiency is inherently limited by the laws of thermodynamics, particularly the Brayton cycle’s ideal efficiency limits. - Material Limitations

Operating gas turbines at higher temperatures improves efficiency but requires advanced materials to withstand extreme conditions. Current materials may degrade under high thermal loads, limiting performance. - Cooling Technology

Efficient cooling methods are critical for maintaining the structural integrity of turbine blades and other components. Developing advanced, lightweight, and efficient cooling techniques poses a significant challenge. - Combustion Efficiency

Achieving complete and efficient fuel combustion while minimizing emissions is challenging. Combustion instabilities can lead to reduced efficiency and increased pollutant emissions.