Repair Gas Turbine

Repair Gas Turbine , Over the past few decades, turbine maintenance strategies have changed. These changes can be examined in two parts. A new look at physical assets is the first factor influencing the transformation of the turbine maintenance process.

are comprised of Solar Turbine parts, gas turbine overhaul , field service, flexible service agreements, digital solutions. and technical training in addition to remote web based monitoring and predictive diagnostic capabilities. A Gas turbine is a specialized rotating engine that has the ability to extract and produce the desired energy from a fluid.

Gas Turbine Components , The increasing use of gas turbines in various industries, especially in the oil and electronics industries. such as moving large pumps inside oil and gas pipelines. supplying energy required by factories and special areas away from the network is very significant and significant. . Also in the power generation industry, global grids are very popular as units that can be put into orbit quickly.

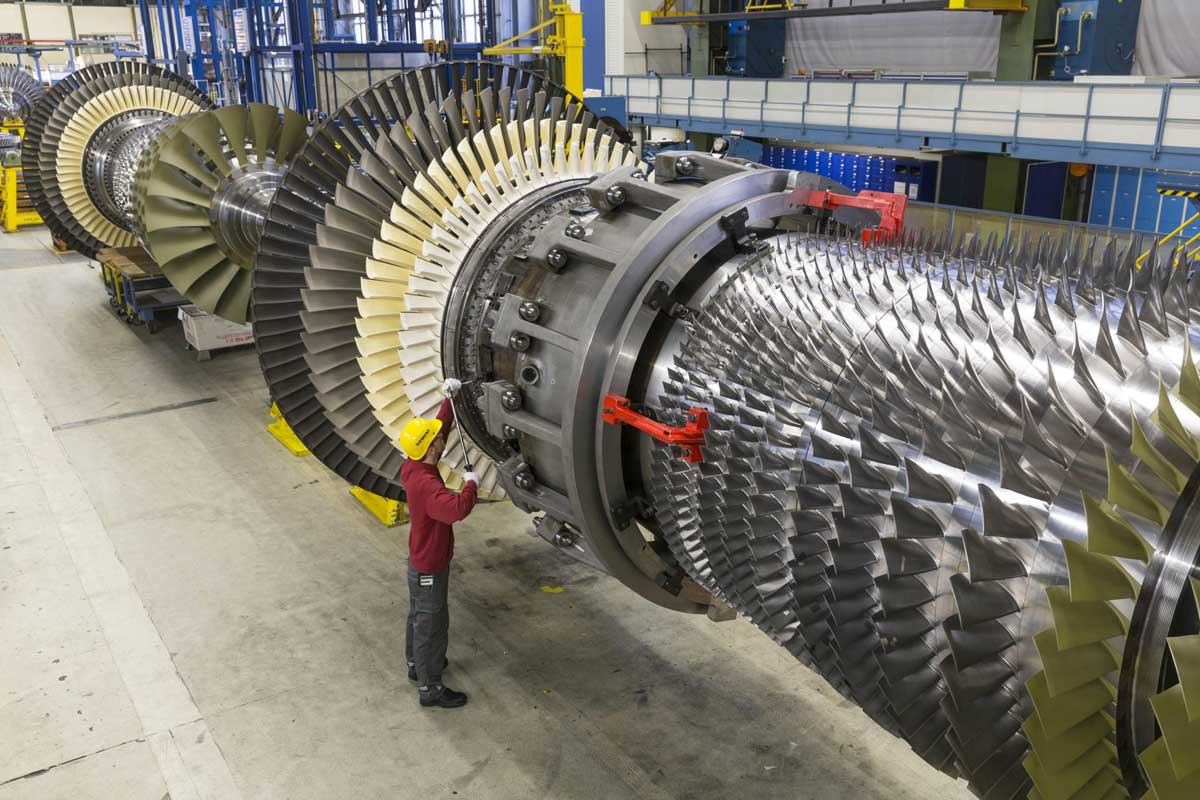

structure of turbines

Another factor lies in the technical nature of the design of the turbines. The structure of turbines has become more complex and sophisticated in recent years. These technical changes require sufficient technical knowledge as well as more periodic inspections at shorter intervals to maintain equipment functions throughout its life cycle.

Gases, steam and water turbines usually have a protective cover around their blades that is responsible for fluid control. Covers and blades can have different geometric shapes, each of which has differences depending on the type of turbine and its application or the type of fluid and efficiency.

Todays, technology is called mother technology, and a country that can design and build gas turbines can produce anything else. Kian turbo tec is one of the best company that Providing services for gas turbines.

Gas turbine repair steps

-

Understanding Gas Turbines

Before we delve into the intricacies of gas turbine repair, it’s essential to have a clear understanding of how these machines work. This chapter will cover the basics of gas turbines, their components, and the common issues that may require repair.

-

Routine Maintenance

Prevention is often the best strategy when it comes to gas turbine longevity. In this chapter, we’ll discuss routine maintenance practices that can help you identify potential issues early on and minimize the need for extensive repairs.

-

Troubleshooting and Diagnostics

Gas turbines can experience a range of problems, from minor hiccups to major malfunctions. Learn how to diagnose issues effectively and understand the key indicators that signal the need for repair.

-

Gas Turbine Repair Techniques

When repair is necessary, it’s essential to employ the right techniques. This chapter will explore various repair methods, including component replacement, welding, and balancing, with detailed explanations and expert insights.

-

Safety Considerations

Gas turbine repair can be a hazardous task. Safety should always be a top priority. Discover essential safety guidelines and best practices to protect both personnel and equipment during repair operations.

-

Preventing Future Issues

After successfully repairing your gas turbine, it’s crucial to take steps to prevent similar issues in the future. This chapter provides strategies for ongoing maintenance and monitoring to ensure long-term reliability.

-

Finding Professional Help

Not all gas turbine repairs can be handled in-house. Learn how to select a qualified and experienced service provider when the need for professional assistance arises.

-

Case Studies

Explore real-world case studies of gas turbine repairs, showcasing successful repair projects and the lessons learned from each situation.

Gas turbine efficiency

Each gas turbine efficiency has a compressor to compress the air. a combustion chamber to mix the fuel with the air and its combustion. and a turbine to convert the internal energies of the hot, high-pressure gases into mechanical energy.

Part of the mechanical energy generated by the turbine is used to turn the compressor of the gas turbine compressor. and the rest of the energy produced, depending on the intended use for the gas turbines, may cause the electric generator to rotate.

Gas turbines are used in a wide variety of applications, including power generation, industrial processing, and aircraft propulsion. They are highly efficient and reliable machines, but they can experience wear and tear over time. This can lead to performance problems, costly downtime, and even catastrophic failures.

Regular gas turbine maintenance and repair can help to prevent these problems. A qualified technician can inspect your turbine for signs of wear and tear, and make necessary repairs to keep it running smoothly. Common repair procedures include:

Here are some tips for finding a qualified gas turbine repair technician:

Get recommendations from friends, family, or colleagues.

Ask your gas turbine manufacturer for a list of recommended technicians.

Check online reviews.

Interview several technicians before making a decision.

By following these tips, you can find a qualified gas turbine repair technician who can keep your turbine running smoothly and efficiently.

Gas Engine

Gas Engine is an internal combustion engine of rotary machines that operates on the energy of combustion gases. It is mainly used in power plants, but helicopter engines, passenger aircraft engines, warplane engines and ship turbine engines are also types of gas turbines.

On the other hand, the financial dimension of the breakdown of this equipment. the seal of approval on the need to pay attention to this issue and also take preventive measures to increase the effectiveness of the maintenance and repair process of this valuable equipment.

In line with the importance of turbine maintenance in this article, we have tried to focus on the technical part, structure and performance of this equipment and also pay special attention to the maintenance of turbines.

Commissioning Gas Turbine Installing a gas turbine in this power plant, in addition to increasing productivity, will bring many financial benefits by reducing environmental pollution and saving maintenance and support costs.

Solar Taurus

are comprised of Solar Turbine parts, gas turbine overhaul , field service, flexible service agreements, digital solutions. and technical training in addition to remote web based monitoring and predictive diagnostic capabilities.A Gas turbine is a specialized rotating engine that has the ability to extract and produce the desired energy from a fluid.

Each gas turbine efficiency has a compressor to compress the air. a combustion chamber to mix the fuel with the air and its combustion. and a turbine to convert the internal energies of the hot, high-pressure gases into mechanical energy.

Compressor Overhaul

A compressor is a critical part of a gas turbine,responsible for compressing air before it enters the combustion chamber.

A compressor overhaul focuses specifically on servicing or replacing the components of the compressor system to ensure it operates efficiently and reliably.

Key Differences between Compressor overhaul & Gas turbine repair

| Aspect | Compressor Overhaul | Gas Turbine Repair |

|---|---|---|

| Scope | Limited to the compressor system only. | Comprehensive, covering the entire gas turbine system. |

| Components Serviced | Only compressor-related components like blades and rotors. | Includes turbine blades, combustion chambers, bearings, and other systems. |

| Objective | Restore compressor function and aerodynamic efficiency. | Restore full operational capability of the entire system. |

| Complexity/Scale | Typically less complex than a full gas turbine repair. | More involved, requiring multi-system analysis and repairs. |

| Cost and Time | Often lower cost and shorter time frame compared to a full repair. | Can be more expensive and time-consuming due to its broader scope. |